A lurking peril

PEOPLE WHO HAVE FILLED scuba cylinders, refilled oxygen cylinders, or boosted a gas mix are familiar with using flexible hoses. Some hoses are covered with a durable rubber or thermoplastic jacket, while others appear even sturdier with a braided stainless-steel mesh on the outside. Correctly specified hoses are rated to pressures of up to 6,000 psi (414 bar).

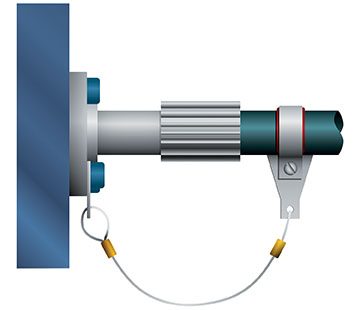

When we first learn the basics of high pressures in hoses and cylinders, we are aware of the potential for serious injury to ourselves and those around us. If hoses fail, the results can be ear-shattering sounds, parts as projectiles, or an escaping gas stream that is strong enough to take out an eye. Without suitable restraints, hoses can whip around with sufficient force to amputate a limb.

Complacency often takes over in most cases, as hoses are sturdy and designed to be handled frequently and subjected to all kinds of abuses. But the risks never diminish, only our perception of risks.

The keys to hose safety are regular inspection, competent use, and replacement according to the manufacturer’s guidelines. Hose replacement is necessary with regular use and should occur more frequently with high usage or in humid areas where metals corrode easily.

The DAN Risk Assessment Guide for Dive Operators and Dive Professionals, which is available as a free download on DAN.org, contains a series of recommendations to address these risks. This information relates to selecting materials and manufacture, hose installation and use, and inspection and maintenance.

Some key recommendations for hose safety include the following:

Hose restraints on both ends can dramatically reduce the consequences of failures.

Image by Brandon Brownell

- Keep flexible hose lengths to a minimum. Using rigid pipes to reduce the length of flexible hoses is the best practice. Hoses should not exceed 6.5 feet (2 meters) and should always be fitted with restraints at the attachment points on both ends. Keep them away from occupied areas, and place long hoses in a protective conduit or covered channel.

- Choose hoses with antiwhip characteristics and kink-resistant materials suitable for high-traffic areas, abrasive contact, and typical dive environments. Their ratings should well exceed the maximum possible pressures generated by the equipment in use.

- A key component is how the end fittings are affixed to the hose. Purchase hoses from reputable suppliers, and have an inspection of end fittings at the top of your checklist.

- Regular inspection of a hose’s condition and monitoring the competence of people handling hoses will provide greater safety assurance.

- It is difficult to provide an absolute requirement, but good practice is to either inspect and hydrostatically test all gas hoses or replace them every five years, depending on the manufacturer’s instructions.

Taking these steps will help you lower the risk of a serious accident. Hoses are usually designed for extreme use and are unlikely to fail if handled carefully, regularly monitored for condition, and replaced when they show warning signs of damage due to wear, corrosion, or excessively rough handling.