Reliable measurement of oxygen is the technology that makes mixed-gas closed-circuit rebreathers (CCRs) possible. For the past 50 years, all electronic CCRs but one have relied on the system invented by marine scientist Walter Starck for the Electrolung, the first commercial CCR. Introduced in 1968, Starck’s design featured three electrochemical oxygen (O2) sensors along with a “voting logic” protocol to address the unreliability of individual sensors. Recent developments, however, suggest that Starck’s technological hegemony has reached its zenith.

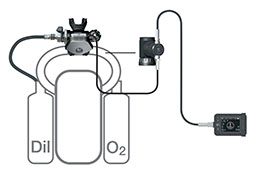

In March 2017, Poseidon Diving Systems began shipping the first digital solid-state CCR sensor, which promises to bring far greater accuracy and reliability to oxygen measurement. This optical sensor is configured to serve as an offboard supplement to the galvanic sensors used in Poseidon’s MKVI and SE7EN rebreathers. The Sweden-based company also plans to incorporate the sensor into its SE7EN rebreather within the next year and has offered to license the technology to other manufacturers.

Avon Underwater Systems has also announced plans to release an optical O2 sensor that will be used in its new MCM100 military rebreather. The MCM100 is the brainchild of business development manager Kevin Gurr, who sold his company to Avon after inventing the Sentinel and Hollis Explorer sport rebreathers. Avon is working with sensor developer Polestar Technologies, which is also building an optical carbon-dioxide (CO2) sensor (see Gear, Alert Diver, Winter 2016).

This long-anticipated development is great news for rebreather diving, which still suffers from a fatality rate that has been estimated as high as 5-10 times that of open-circuit scuba. Galvanic sensors are regarded as the Achilles’ heel of CCRs; numerous fatalities and near misses are attributable to their failures. Optical sensors promise to be a significant safety improvement.

Given the size and economics of the sport-diving market, it will probably be some time before optical sensors are commonplace. Most insiders say it’s unlikely that optical sensors will on their own measurably reduce fatalities. They will go a long way, however, toward advancing rebreather technology from its current test-pilot status to something closer to commuter status.

A Starck Vision

Starck’s Electrolung used three newly invented polarographic sensors whose conductivity varied proportionally with oxygen levels. Starck and his colleagues would assemble and calibrate fresh sensors for each day of diving. Because of the sensors’ inherent fallibility, Starck incorporated a voting logic protocol that determined the partial pressure of oxygen (PO2) by averaging the output of the two sensors whose readings were closest to each other’s and ignoring the third.

Within a year another start-up, BioMarine Instruments, used Starck’s sensor design for their CCR-1000, the predecessor of the U.S. Navy’s Mark 16 (MK 16). Their version replaced the polarographic sensors with galvanic fuel cells, which did not require a power supply. Even though early cells had to be replaced every few weeks, they quickly became the industry standard.

Galvanic sensors, which are essentially wet-cell batteries that generate a millivolt current proportional to the PO2 in the system, have greatly improved since that time, but as any rebreather diver knows, they are finicky at best. The sensors have a finite lifetime, can become current limited and suffer from manufacturing irregularities and individual variation. They can also have problems with calibration, temperature compensation, condensation and handling. Additionally, in some circumstances, Starck’s voting logic protocol has been shown to offer little more reliability than a single sensor.

In Search of the Holy Grail

Poseidon jump-started its entry into the rebreather business in 2005 by licensing Bill Stone’s Cis-Lunar technology and has been a major innovator in recreational rebreathers. In 2007 the company introduced its Active Sensor Validation (ASV) system, which automatically validates its primary O2 sensor every five minutes, performs other tests every minute and incorporates a secondary redundant sensor — arguably the first significant innovation in O2 sensing since the Electrolung.

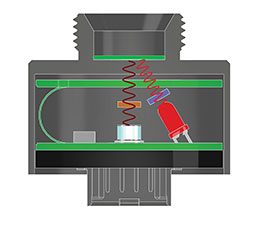

Next the company embarked on a quest to replace its galvanic sensors with more reliable technology. The result is a new optical sensor that uses luminescent quenching. Essentially, an LED light excites the underside of special polymer surface, which is covered with a hydrophobic membrane and exposed to the gas in the breathing loop. A digital color meter then measures the responding change in fluorescence, which is dependent on oxygen tension, and an algorithm calculates the PO2 (see diagram).

“For the past five years my holy grail has been sorting out oxygen sensing,” explained Poseidon CEO Jonas Brandt, who expects their new sensor to last more than 3,000 dive hours. “I feel we’ve succeeded.” The sensor comes calibrated from the factory and requires Poseidon’s M28 dive computer to operate; it cannot be substituted for an analog sensor.

Stone associate Richard Pyle and a team of ichthyologists at Bishop Museum in Honolulu, Hawaii, have been field testing the new sensors for more than a year and generating copious data that’s being used to refine the sensor’s algorithm. The SE7EN rebreather records 30,000 to 40,000 events per hour. Pyle estimated that they have roughly 1,000 dive hours on the sensors to depths as deep as 500 feet. “The sensor has been incredibly reliable and much more granular than a galvanic cell,” he said. “We had numerous incidents in which the galvanic cells did not agree with the solid-state sensor; in all cases the galvanic cells were wrong.”

Brandt said the company had preorders for about 80 of the $1,495 sensors and CPOD offboard adapters as of March 2017. Poseidon plans to incorporate the new sensor into its ASV system in the next year and is in discussions with at least one other manufacturer interested in licensing the technology.

Polestar’s new sensor is also based on luminescent quenching but features a consumable polymer-sensing strip that must be replaced periodically. The company initially developed the sensor’s chemistry for NASA, which needed a reliable sensor for monitoring space-station gardens. It sells about $1 million of the sensors annually for the bioreactor market and is now adapting them for diving.

“Many industries are converting from electrochemical to optical sensors because of reliability,” said James Kane, Polestar’s vice president of technology and product development.

What Are You Breathing?

What will a rock-solid optical O2 sensor mean for divers? For one thing, they will likely have a single PO2 to monitor instead of three. Whether the sensor will make rebreather divers safer is a more nuanced question. As human factors consultant Gareth Lock explained, “Safety is a systems concept, not a product feature. There is no such thing as a safe rebreather in itself.”

Nevertheless, removing divers’ uncertainty about exactly what they are breathing at any point during the dive can only enhance safety — as will completing their checklists.

| © Alert Diver — Q2 2017 |

|---|

| © Alert Diver — Q2 2017 |