Eliminating the quarter-turn back

“Turn on your cylinder, and then close it one-quarter turn.” Many divers have heard this instruction during and after their scuba certification classes. Have you ever wondered why this procedure was recommended? Is this practice still necessary?

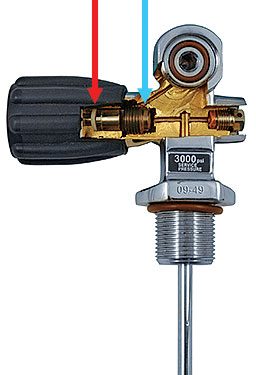

In the past, valve designs were not as sophisticated as they are today. Overtightening older valves could cause damage in two ways. When forced beyond fully open, a seal inside the valve near the handwheel, called the valve stem seal or packing, would become damaged over time from being squeezed against the valve bonnet nut. Divers feared that the valve would stick open and delay any ability to shut it off in an emergency. The second cause of damage was from closing the valve too tightly, which could affect a different seal located at the end of the handwheel’s inner part, called the valve seal or insert, by pressing it onto the seat.

In both cases the valve would start to leak either through the handwheel or out of the valve outlet. To compensate for the leak, divers would close the valve even more tightly, which would cause an even greater leak over time.

Modern valve design, however, protects both the valve stem seal and valve seat. Less force is needed to fully close or open the valve, and valves are now less prone to leaking or sticking open. While the quarter-turn-back practice is still present in other industries to prevent valve damage and ensure that valves do not stick open, the dive industry is moving away from this practice because people unfortunately keep getting injured.

Divers Alert Network® has recorded 13 incidents since 2013, including one that resulted in a fatality and another that required a hospital stay (see “An Emergency Ascent Just in Time” by Christina Hepburn in the Spring 2017 Alert Diver). These are reported incidents associated with the quarter-turn back, but we can safely assume that a significant number of such incidents go unreported.

Imagine this scenario: Your valve is closed, and when you put your primary regulator in your mouth before entering the water you discover that you cannot draw a breath. You reach back and turn your cylinder valve all the way open before entering the water. Injury averted.

Now imagine that you get confused about whether you opened or closed your valve. You could mistakenly close the valve and open it only a quarter turn instead of the other way around. Before entering the water, you can breathe fine from your primary regulator. When you enter the water and start descending, however, it gets harder to breathe, and eventually you cannot draw breath from your regulator.

When diving, your lung volume stays the same, but you require more air to fill your lungs due to the increase in pressure. The increased need also means that the air needs a larger opening inside the valve to provide a greater flow, or more dense gas, as pressure increases. When a valve is only partially open, it will limit denser air flowing through it and will not supply the same amount of air as it would at shallower depths. This flow limitation results in the starvation of your breathing air.

Another contributing factor is restriction due to sonic velocity, which happens when the gas flow reaches the speed of sound. When you first open the cylinder’s handwheel, it creates a flow path inside the valve, and air passes through the outlet. If the valve is not sufficiently open, it can constrict the flow, causing an increase in velocity to maintain the required flow. This increase could cause the gas to approach the speed of sound, at which point it will “choke” and limit the flow of air into your regulator and therefore your lungs.

Make it your standard practice to gently and completely turn on your air. If you’re an instructor, consider not teaching students the quarter-turn back. Dive operations should instruct their staff not to perform the quarter-turn-back practice on customers’ cylinders. Confusing the direction of a handwheel does not happen only to new or inexperienced divers. There have been anecdotal reports of divemasters on busy boats accidentally turning off customers’ cylinders and then performing only a quarter-turn on.

An additional safeguard that will further ensure that your valve is open is to take a couple of breaths from your regulator while looking at your pressure gauge. The needle should hold steady; if it bounces up and down with each breath, your cylinder valve is not fully open.

By fully opening your valve, you can eliminate one cause of a possible incident and make your diving safer.

© Alert Diver — Q1 2021