Unlike an open-circuit diver, who breathes a known, predetermined gas mixture (You do analyze your gas before diving, don’t you?), a rebreather diver respires an artificial atmosphere that changes dynamically with depth over the course of a dive.

An electronic rebreather has two jobs: to measure and maintain a preset level of oxygen (partial pressure of oxygen, or PO2) using oxygen (O2) sensors and a controller, and to remove the diver’s exhaled carbon dioxide (CO2) by means of a chemical scrubber. Until recently there was no way to detect the presence of CO2 in the breathing loop — that is, to know if the rebreather was working properly.

CO2 detection has long vexed the U.S. Navy, which has spent millions of dollars over the past 50 years in search of a solution, and for good reason: Hypercapnia from elevated CO2 levels in the loop is a major hazard in rebreather diving. It can lead to incapacitation, loss of consciousness and death in amounts greater than 0.01-0.02 atm.

Divers tend to be poor at detecting increased CO2, especially when exerting themselves. By the time they detect it, the situation is usually perilous, requiring a rescue rather than a bailout. Appropriately dubbed the dark matter of rebreather diving, CO2 may be responsible for or a contributing factor in as many as a third of sport rebreather fatalities.

In the past five years, as a result of a breakthrough in commercial technology, several sport rebreather manufacturers have introduced nondispersive infrared (NDIR) sensors that warn divers of elevated CO2 levels, indicating a possible scrubber failure. Though the technology is still in its infancy, it holds promise for improving diver safety.

Meanwhile, the Navy Experimental Diving Unit (NEDU), which has tested dozens of NDIR devices with limited success due to problems with water vapor and pressure effects, is currently beta testing an innovative sensing film for use in oxygen rebreathers that could revolutionize CO2 detection.

Dark Matter in the Loop

Divers produce about 0.9 liters of CO2 for every liter of O2 they consume. A properly functioning rebreather removes this gas from the breathing loop. Even so, CO2 can accumulate in several ways. First, inspired CO2 levels rise exponentially once the scrubber reaches depletion, which is known as “breakthrough.”

Feeling lucky? Although manufacturers publish a worst-case scrubber duration, actual duration can vary high or low by a factor of four times depending on a diver’s profile and workload, the water temperature and even the brand of CO2 absorbent used in the scrubber.

Improperly filling or installing the scrubber or forgetting to grease the scrubber O-ring can result in channeling or bypass, allowing CO2 to be rebreathed. So can a dirty “mushroom valve,” a one-way valve that directs the diver’s exhalation to the scrubber.

Finally, divers eliminate CO2 by breathing, and CO2 levels in a rebreather diver’s arterial blood can rise to dangerous levels as a result of insufficient breathing. In fact, the combined effects of immersion, static lung loading, increased gas density and having to push gas through the loop with the lungs can reduce a rebreather diver’s capacity to ventilate by about 50 percent at 100 feet, and it continues to decrease with depth.

In the absence of a means to detect CO2, military divers have relied on strict protocols for preparing their rebreathers, including a five-minute prebreathe to detect possible problems. However, a recent study1 found that 90 percent of subjects failed to detect a partially faulty scrubber during the prebreathe. This illustrates the great need for reliable sensors.

In 2001, under pressure to reduce “scrubber crashes” in the fleet, NEDU released a patented scrubber thermal array that measures the heat of the chemical reaction as CO2 moves through scrubber. AP Diving developed its own array, called a TempStik, in parallel. Though not foolproof, these devices function as a sort of gauge to estimate how much CO2 absorbent has been used and how much remains, greatly reducing uncertainty about scrubber duration.

The Sensei of Sensors

The Navy wants to improve safety by equipping rebreathers with both a scrubber gauge and one or more CO2 sensors. Interestingly, sport rebreathers were first to incorporate the combined solution.

In 2008, rebreather pioneer Kevin Gurr of VR Technology Ltd. launched the Sentinel, which included a thermal array licensed from NEDU along with the then-groundbreaking low-power NDIR sensor from Gas Sensing Solutions (GSS). He later incorporated these into the Explorer, which was sold to Hollis Inc. AP Diving introduced its own version of the GSS sensor for its rebreathers in 2014. rEvo Rebreathers has also licensed NEDU’s array.

The GSS sensor projects an infrared LED light through a sample of gas exiting the scrubber and calculates CO2 levels based on the amount of light absorbed. Unfortunately water vapor also absorbs infrared light and thus reads as CO2, so a barrier must be used to keep the sensor dry. This is no small task in a 100 percent humid environment, but it can usually be achieved with replaceable filters.

The software also requires extensive calibration data because light absorption changes with pressure in a noncomputable way. Because of its placement, the sensor is unable to detect a mushroom value failure or arterial CO2 buildup.

Although the sensors have proved finicky and in some cases have had to be replaced, most users are supportive. “The current sensor is a fantastic addition to rebreather safety,” an APD diver told me. “It just seems like it is still in development.”

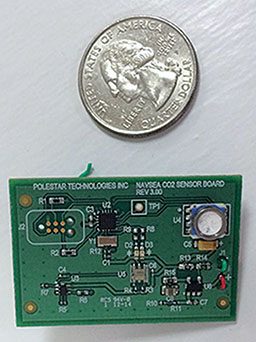

The game changer may be a new sensor technology developed by Polestar Technologies Inc. that NEDU is currently testing for use with oxygen rebreathers. At its core is a quarter-sized disc of polymer film that changes from blue to yellow in a reversible and predictable way when exposed to CO2. Notably, moisture does not affect its operation.

A tiny white LED light illuminates the disc from a sealed pot below that houses the electronics. A digital meter reads the color, which is converted to the CO2 level. The heads-up display gives a green light for good and flashes red when CO2 levels reach a predetermined limit. It can easily be integrated into a mixed-gas rebreather.

In the future the device could be adapted to fit inside a rebreather mouthpiece and measure the end tidal CO2 in the diver’s exhalation — the holy grail of CO2 sensing — to estimate arterial CO2 levels. Future rebreathers may sport multiple sensors.

Although the technology exists, only six of the more than 20 rebreather manufacturers offer some form of CO2 protection, and only two offer both an array and sensor. Many don’t see the need. As one manufacturer told me, “Divers just need to learn to pack their scrubber properly.”

Given that rebreather fatality rates have been estimated to be five to 10 times higher than open-circuit rates, perhaps the question is better put to the divers themselves: “Do you want to know what you’re breathing, or not?”

Reference

- Deng C, Pollock NW, Gant N, Hannam JA, Dooley A, Mesley P, Mitchell SJ. The five-minute prebreathe in evaluating carbon dioxide absorption in a closed-circuit rebreather: a randomized single-blind study. Diving Hyperb Med. 2015; 45(1):16-24.

© Alert Diver — Q1 Winter 2016