Since divers don’t have gills, we have to carry our own air supplies with us if we want to spend any time underwater. For the average recreational scuba diver this means strapping on a tank of compressed air. However, human bodies are not designed to breathe compressed air, so we need a way to transform it into something our lungs can comfortably handle. That’s the job of a scuba regulator.

Scuba Reg Smackdown

In one corner there’s the scuba tank, filled with compressed air or nitrox. This high-pressure (HP) air can range from 2,250 pounds per square inch (psi) in older steel 72 tanks to 3,000 psi in a typical aluminum 80, to around 3,500 psi in modern high-pressure steel tanks. Recreational divers in Europe may use even higher-pressure tanks.

In the other corner there’s the diver who needs air at ambient pressure to breathe. On the surface, ambient pressure is 14.7 psi; at 66 feet deep it is about 44 psi (3 atmospheres at 14.7 psi per atmosphere).

In between tank and diver, there’s the scuba regulator. A regulator can be broken down into three basic components:

- the first stage that attaches to the scuba tank

- the second stage the diver holds with his mouth

- the interstage hose that connects them together

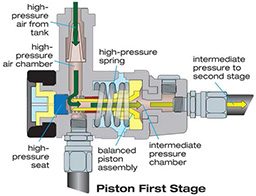

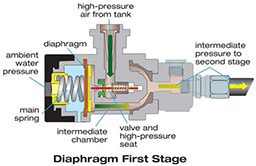

The job of the first stage is to take the HP air in the tank and step it down to what’s called intermediate pressure (IP), which, depending on the regulator, normally ranges from 125 to 145 psi more than ambient pressure.

When a regulator is connected to a tank and the tank valve is opened, HP air flows into the first stage’s HP chamber. Next it flows into the IP chamber, where air pressure is reduced. From there it travels through the hose to the second stage, where IP air is stepped down to ambient pressure before entering the diver’s lungs.

This step-down air-delivery process is triggered when — and only when — the diver inhales. Because of this, scuba regulators are referred to as “demand-type” air-delivery systems.

Piston and Diaphragm First Stages

Separating the HP and IP chambers in the first stage is a mechanism that controls the flow of air from one chamber to the other. Depending on the regulator, this mechanism will be either a piston or a diaphragm.

In a piston system, when a diver takes a breath from his second stage, the pressure in the first stage IP chamber drops. This causes a spring to expand, which draws the piston off its seat and opens the channel between the HP and IP chambers. Air then flows from the HP chamber into the IP chamber, compressing the spring and returning the piston back onto its valve seat. As the diver inhales again, the cycle repeats.

In a diaphragm system there is a soft cover (like a flexible drum head), which is drawn inward from the force of the expanding main spring as the diver inhales and the IP chamber empties. This separates the seat seal between the HP and IP chambers, allowing air to flow. When the IP chamber fills, the rising pressure forces the diaphragm outward. This compresses the main spring and reduces the force exerted onto the seat seal, closing the air passageway.

Balanced and Unbalanced First Stages

One of a regulator’s primary functions is to keep the IP as consistent as possible while dealing with the continuous change in the supply pressure as the tank is breathed down and the change in ambient pressure as the diver changes depth.

An unbalanced first stage is susceptible to IP variation as tank pressure is reduced or as depth changes. Consequently, as a diver goes deeper or as he breathes the tank down, the inhalation effort may increase.

A balanced first stage, in contrast, is able to maintain a more consistent IP regardless of conditions. This is accomplished through the inclusion of a balance chamber that uses tank pressure to apply equal pressure to both sides of the valve head. This results in consistent breathing performance regardless of depth or air supply.

The Second Stage

The second stage’s job is to take IP air and step it down to ambient pressure so the diver can enjoy an inhalation effort as close to normal topside breathing as possible.

As the diver inhales, pressure in the second stage casing drops below ambient pressure, which forces the diaphragm toward the diver’s mouth. This causes it to press against a demand lever, which allows an inlet valve to open and air to flow. Upon exhaling, the diaphragm is forced away from the diver’s mouth, taking the pressure off the lever and closing the inlet valve. At the same time, the exhalation pressure forces the exhaust valve open, allowing exhaled air to be released into the water column.

Like first stages, second stages are either balanced or unbalanced. Balanced second stages reduce the “cracking effort,” or the amount of “suck” required to initiate airflow with each breath. This makes for an easier-breathing regulator.

Some second stages also offer user adjustments that allow the diver to take a more active role in regulating airflow. The two basic types are the dive/predive switch (DPD) and the breathing-resistance knob.

The DPD is primarily a surface adjustment. In essence, it detunes the regulator by reducing breathing sensitivity. This is often done through the use of a pivoting vane located right inside the mouthpiece orifice. When turned at an oblique angle, the vane deflects airflow, creating turbulence inside the casing and making the regulator less prone to freeflow when it’s not in the diver’s mouth.

The breathing-resistance knob is more of an at-depth adjustment. It enables the diver to alter the breathing effort based on diving conditions. Dialing “in” exerts pressure on the second-stage spring. This pushes on the seat, increasing the effort required to breathe. This can be useful for minimizing positive pressure when swimming into a current. Dialing “out” eases pressure on the spring and seat, making it easier to generate airflow. This can be useful when descending to deeper depths.

Put it all together and divers have a comfortable and reliable breathing system that supplies a steady flow of air, available on demand.

© Alert Diver — Q2 Spring 2012