Probably nothing is more important to divers than their breathing gas. Whether they use compressed air, nitrox or some exotic mix, having sufficient breathing gas ranks high on divers’ predive checklists. But just as important as the quantity of gas is its quality. While breathing gas contamination is considered rare in recreational diving, it does happen. Even trace amounts of contamination can lead to incapacitation, unconsciousness or even death.

Contamination of breathing gas takes a variety of forms and can be caused by a wide spectrum of conditions. The most common cause of breathing gas contamination involves the compressor system. In other cases, contamination can occur right in a diver’s cylinder. Improper gas mixtures can also be considered a form of contamination.

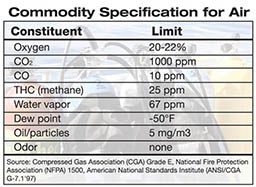

While there are quality standards compressed breathing gases must meet, divers should still take responsibility for ensuring the quality of their own gas. Happily, there are several options available to divers when it comes to analyzing gas mixtures.

The Sniff Test

Perhaps the simplest technique of air quality analysis is the “sniff test,” wherein the diver opens the valve and smells the escaping gas to detect suspicious odors. This crude test is effective to the extent that gross contamination in the form of oil, diesel fumes and other combustion products can sometimes be detected by odor and/or taste. However, since carbon monoxide (CO) is both colorless and odorless, breathing gas can pass the sniff test and still be contaminated by CO. A more accurate solution to analyzing is the use of a portable sensor.

CO Detectors

Color-change sensors are often used for measuring CO levels and include both qualitative and quantitative devices. Qualitative devices use a color-change element that gives divers a go/no-go indication. Be aware, though, the color change indicates only that the air sample exceeded acceptable contamination limits; it doesn’t indicate by how much. Quantitative color-change sensors use a small pump to draw a measured quantity of air (usually 50 cc’s) through a calibrated color-change tube. The CO in the air sample reacts chemically with the sensor material in the tube, causing it to change color. A scale on the side of the tube measures how much chemical has changed color and reports the actual concentration of CO.

Electronic CO-monitoring devices subdivide into two categories: metal-oxide detectors and electrolytic detectors. Metal-oxide detectors utilize sensors containing, not surprisingly, metal oxide. In the presence of CO, the metal oxide gives up its oxygen, changing to a pure metal and generating heat in the process. The amount of temperature change can be correlated to the CO level in the sample, and the result is displayed by the device.

Electrolytic CO detectors work like tiny batteries, with platinum electrodes dipped in an electrolyte. The presence of CO increases the generation of electrical energy, which can be correlated to the concentration of CO. These are perhaps the most sensitive and accurate types of CO sensors, but they are also more expensive and use more power to operate.

When choosing a CO monitor, give careful thought not only to price, but also to the type of diving you enjoy and the logistics of taking the measurements.

Nitrox Analyzers

The growing popularity of nitrox has undoubtedly done a lot to improve the state of oxygen-monitoring technology for divers. Though the gas analyzers commonly seen in dive shops and on dive boats are often called “nitrox analyzers,” it’s equally accurate to call them “oxygen sensors,” as what these tools are really monitoring is the level of oxygen in a given nitrox gas mixture. Probably the most common type of oxygen sensor uses a galvanic fuel cell that generates a weak electrical current proportional to the concentration of oxygen. Although monitors using this technology can usually measure oxygen content to within a 0.1 percent margin of error, they can be fooled. The monitor may provide a reading in “percent oxygen,” but it is actually measuring the partial pressure of oxygen. Change the pressure, and the oxygen reading changes, too.

Changes in temperature will also affect the rate of the chemical reaction in the fuel cell and, consequently, the reading of the monitor. While nitrox analyzers typically have temperature-compensation circuitry, problems can arise when a cold monitor is suddenly taken into warm conditions or vice versa. Always allow your nitrox analyzer to reach ambient temperature and calibrate the monitor to a known standard, typically compressed air at 21 percent, before putting it into action.

Yet another problem that divers should be aware of is poor sampling technique. If the monitor is not properly used to make sure it is reading only the gas coming from the cylinder, it might be measuring a diluted mixture of ambient gas as well as the gas coming from the nitrox cylinder. Always read and follow the manufacturer’s instructions to ensure you’re getting accurate results.

Maintenance Matters

Taking proper care of your gas-analyzing equipment is of critical importance. Always store your analyzers in a cool, dry place. Avoid rough handling and exposure to seawater and other wet conditions. Analyzers usually require a power source, so make certain yours is fresh. When on the road, spare batteries can be a lifesaver. Remember that many sensors have a limited life, so track the time and use of your analyzer, and carry a spare when traveling. Of course, dive operations and liveaboards that offer nitrox will have their own sensors. Whether you choose to use your personal nitrox analyzer or use those on location, understanding the concept and the proper use of gas analyzers will help to make you a safer diver.

Bad gas is not a likely hazard for recreational divers, but the consequences of undetected contamination can be a serious matter. By using portable gas analyzers, divers can limit the risk and enjoy a greater level of safety while diving.

Know the Symptoms

NOTE: If you experience any symptom associated with gas contamination, abort the dive and exit the water.

General contamination: Contamination of breathing gas can come in a variety of forms. Some of the most common symptoms are an oily taste, oily smell or other foul odor.

Carbon monoxide poisoning: The most common symptoms of CO poisoning are headache, dizziness, weakness, nausea, vomiting, chest pain and confusion. High levels of CO in the breathing gas can cause loss of consciousness and death. Unless suspected, CO poisoning can be difficult to diagnose because the symptoms are common to a larger spectrum of maladies.

Oxygen toxicity: The most common symptoms of central nervous system (CNS) oxygen toxicity include tremors, ringing of the ears, nausea, tunnel vision and seizures.

© Alert Diver — Q4 Fall 2010