Incidents involving bad breathing gas — be it air, nitrox, trimix or another mixture — are rare, yet they do occur. Health effects on divers vary depending on the contaminant breathed. Among the most severe symptoms of breathing contaminated gas are impaired judgment and loss of consciousness, both of which may be deadly underwater.

Sources of contamination include hydrocarbons from compressor lubricants, carbon monoxide (CO) from engine exhaust (or overheated compressor oil) and impurities from the surrounding environment such as methane and carbon dioxide (CO2). Dust particles in breathing gas can also be hazardous, potentially impairing respiratory function or damaging diving equipment. Excessive moisture can cause corrosion in scuba cylinders and other dive gear and may cause regulators to freeze due to adiabatic cooling (heat loss subsequent to increased gas volume).

Recommendations for Compressor Operators

Compressor operators can help prevent gas contamination and mitigate the risk of dive accidents in several ways.

Attentive compressor maintenance. Proper compressor maintenance helps ensure breathing-gas quality as well as extends the life of the compressor. Breathing-gas contamination is less likely in well-maintained and properly functioning compressors. If maintenance is neglected and the compressor overheats, the lubricating oil may break down and produce CO and other noxious byproducts.

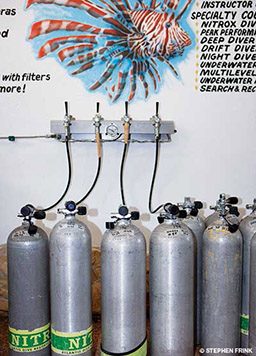

Effective procedures. A fill checklist can help ensure safety procedures are remembered when cylinders are filled. Before starting to fill tanks, the operator should inspect the compressor’s filters for damage and note the presence of contaminants such as cigarette smoke, paint fumes or engine exhaust near the intake. If the operator notes any chemical or oily odors after filling has started, he should shut down the compressor immediately. Other useful strategies for reducing the risk of gas contamination include keeping records of air fills and maintenance, ensuring operator qualifications are up to date, using proper oil and filters, and maintaining a clean and organized tank-filling room.

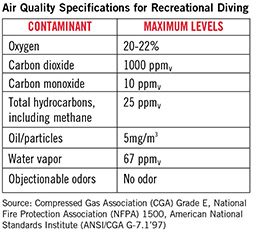

Air-quality testing. As a diver descends and ambient pressure increases, the amount of gaseous contaminants breathed also increases. This explains why a contaminated gas that is not toxic at the surface may be at depth. Breathing gas must be tested for a variety of contaminants both regularly and continuously to ensure compliance with diving-adjusted contaminant levels.

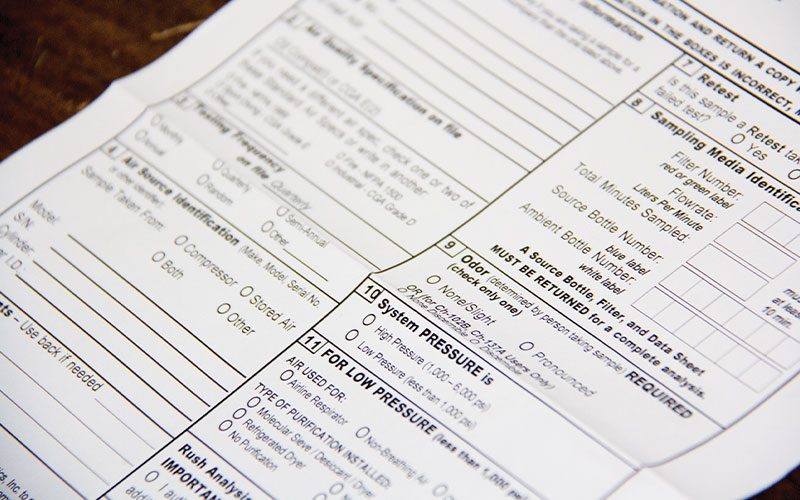

Compliance with breathing-gas quality standards is not strictly enforced, and most of the responsibility for testing lies with the operator. Several methods of testing are available to compressor operators, and they vary in price and complexity. Continuous CO-monitoring devices include electrochemical sensors with color indicators. Devices that continuously monitor moisture level are also available. Operators can send a breathing-gas sample to an accredited laboratory for analysis of oxygen, CO, CO2, moisture, oil/hydrocarbons and even particulate matter; this is recommended on a quarterly basis.

Recommendations for Divers

Ask questions and be observant. If you are unsure about the breathing-gas quality at a fill station, ask questions about compressor maintenance, procedures and testing. Ask if the compressor operator monitors for CO and how often they send samples to a lab for analysis. Look for posted breathing-gas-analysis reports, and note whether the fill room is clean, organized and well ventilated. Observe the proximity of the compressor intake to sources of exhaust, and look to see whether the compressor has an hour meter that can be monitored for regular maintenance.

Always conduct a predive gas check. If your breathing gas has an unusual odor or taste, do not dive with it — this is a red flag for oil or combustion contamination. However, keep in mind that not all contaminants can be detected this way; CO, for example, is odorless and tasteless. Electronic CO detectors or products such as CO-PROTM can be used to detect the presence of CO in breathing gas. Divers should always use oxygen analyzers to determine the level of oxygen in a nitrox mixture to prevent oxygen toxicity.

Confirming Contamination

Identifying contamination incidents based on symptoms alone is difficult, as the associated symptoms are often similar to other diving-related and nondiving illnesses. If a diver suspects he was exposed to bad breathing gas, he should seek a medical evaluation and have the gas tested. Observing the health of other divers who had their tanks filled at the same source may be helpful in determining whether a diver’s symptoms are related to contamination.

DAN Research

DAN occasionally receives reports of problems from divers breathing contaminated gas, but we suspect this issue is underreported. To encourage divers to report compressed-gas contamination, DAN will assist with gas analysis. If you were involved in an incident possibly related to breathing contaminated gas and you have lawful control of the tank, please preserve the tank and contact DAN Research at 919-684-2948 or at DAN.org/DivingIncidents.

References

- Burman F. Scuba air quality. Alert Diver Southern Africa. Autumn 2013: 14-18.

- Millar IL, Moudley PG. Compressed breathing air: the potential for evil from within. Diving and Hyperbaric Medicine. 2008; 38: 145-51.

© Alert Diver — Q2 Spring 2014