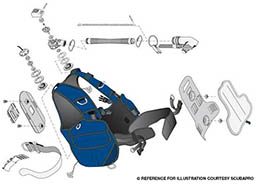

One of the most mechanically complex items of dive gear is the buoyancy compensator device (BCD). BCDs come in a variety of sizes and styles, from slim, warm-water jackets to high-tech, back-mounted “wings.” Beyond the basic buoyancy control functions, many BCDs incorporate integrated weight systems and/or an integrated alternate-air inflator. Like all dive equipment, BCDs require regular care and maintenance to ensure their various parts stay in reliable working order.

Because a stuck inflator valve, or failure of any of the many BCD components, can soon have a diver singing the BCD blues instead of enjoying a dive, understanding the mechanics of operation and basic maintenance is helpful. Happily, there are several ways to prevent and deal with just about all BCD issues.

Inflator Mechanism

The heart of any BCD is the inflator mechanism, which controls the inflation and deflation of the device. One problem that can really throw a monkey wrench in the works is a sticking or leaking inflator valve. If the auto-inflator valve jams in the valve-closed configuration during a dive, use the oral inflator to sidestep the problem, then have the device serviced.

A leaking valve may require the diver to make constant adjustments, but one that sticks open, allowing the BCD to inflate fully, can represent true danger. A quick-thinking diver might be able to detach the quick disconnect from the BCD, but the concern with this problem is the possibility of an uncontrolled ascent.

While a variety of problems can be at the root of a stuck or leaking inflator, poor maintenance and perhaps even faulty diving technique are likely culprits. If sand, silt or other debris are allowed to enter the inflator mechanism, it can cause the moving parts to jam. Salt crystals and corrosion can also bind the mechanism.

Relief and Dump Valves

All BCDs incorporate one or more overpressure relief valves, which are designed to prevent overexpansion of the bladder. These are generally spring-loaded valves that open when the pressure differential exceeds a specified limit. The valves are sized to prevent overpressurization of the device during a rapid ascent and in the event of a stuck auto-inflator valve. Divers should test this valve as part of their routine maintenance by inflating the device and squeezing it firmly. A sticking valve could be due to deterioration of the valve-seat material or accumulation of salt crystals or other foreign matter. If the valve doesn’t open to release air, it should be professionally inspected and repaired.

A second precaution is to make certain the valve housing is secure. Some models have screw-on housings that hold the valve and spring in place, and these can loosen over time. If the housing unscrews and detaches from the bladder, it leaves a gaping hole in the bladder that renders the BCD temporarily useless.

Dump valves and deflator valves (oral inflators) that don’t fully close can also cause serious problems. Here again, the root of the problem is often inadequate maintenance, leading to contamination that prevents the valves from seating.

Quick Disconnects

Another common trouble spot for many BCDs is the quick disconnect on the auto-inflator mechanism. Exposure to seawater and lack of post-dive cleaning can lead to corrosion and mineral buildups that cause the connector to stick and/or leak. While a sticking or leaking quick disconnect can be cleaned or replaced, prevention is a simple matter of thoroughly rinsing the connector after each day of diving. A shot of silicone lubricant will help keep the connector working smoothly.

Integrated Weight Systems

Integrated weight systems are a popular feature in BCDs, but again, some attention to detail in the preventative maintenance department can help prevent the onset of problems. Worn Velcro fasteners or deteriorated stitching can result in a surprise weight loss. Likewise, improper maintenance and worn components can cause problems with the emergency weight-release function.

Operator Error

Although mechanical failures and malfunctions can occasionally develop, one of the more common causes of BCD problems is operator error. Especially when divers rent or borrow equipment, unfamiliarity with the device is most likely to arise underwater in conditions when it is more difficult to see and operate the buttons. Button confusion can cause a diver to add air to the BCD when less is needed or to vent air when more is needed. One way to avoid the problem is to become familiar with a new, borrowed or rented BCD before entering the water. Familiarize yourself with the appearance of the buttons, and practice operating the inflator/deflator mechanisms by touch alone. If you plan to wear gloves underwater, practice operating the device wearing the gloves.

Preventative Maintenance

The most important key to BCD reliability is preventative maintenance. To keep a BCD operating properly, one would ideally give it a thorough cleaning after each day of diving.

Rinse the BCD and inflator mechanism thoroughly with clean, fresh, preferably warm water to remove all sand, silt and salt deposits. Partially inflate the bladder, and add fresh water via the oral inflator. Then shake the device to rinse the inside of the bladder. An occasional treatment with an algaecide can prevent growth inside the bladder and hose, though check with the BCD’s manufacturer to be sure your chosen algaecide and dilution is safe to use with your particular gear. The integrated safe second regulator on some BCDs should be given the same care and attention given any other regulator.

Check the mechanical integrity of the BCD, taking note of abrasion, deteriorating stitching, worn Velcro fasteners, bent clips and other signs of trouble. Check the security of the inflator hose, overpressure relief valve, dump valves and weight-ditching mechanisms. Before diving, test each function to make certain all valves and components are working correctly.

In addition to routine preventative maintenance, a BCD should receive periodic professional maintenance at least once per year. A professional inspection and tune-up is a bargain if it prevents a dangerous scenario from developing underwater, and it can also give divers some added peace of mind.

Reliable dive gear is essential to safe diving. With proper care and maintenance, we can enjoy reliable service from our gear and avoid the BCD blues.

© Alert Diver — Q2 Spring 2011